Over the past few years, the alternative protein sector has struggled to deliver products that truly compete with conventional animal meat in terms of taste, texture, nutrition and price. Plant-based meats have focused on ground and shredded formats, leaving whole cuts – which is how the majority of meat is consumed – almost entirely unexplored.

With bird flu, climate change, and trade agreements threatening poultry and meat supply chains and prices, the need for high-quality whole-cut alternatives is urgent. Consumers and meat producers need a solution that isn’t a better attempt at existing plant-based meats, but a true replacement for whole cuts, such as chicken breasts.

The Gen3 platform, which was announced last year, stands as one of the most advanced developments in the alternative protein space, designed to replicate meat’s hierarchical structure from microscopic muscle fibers to chunky complex whole cuts. Building on this foundation, the Gen4 platform is a dramatic advancement in both technical capabilities and commercial viability. It achieves unprecedented precision in replicating conventional meat, while scaling up manufacturing throughput. It is arguably the world’s first platform that replicates all perceptible components and structures of conventional meat.

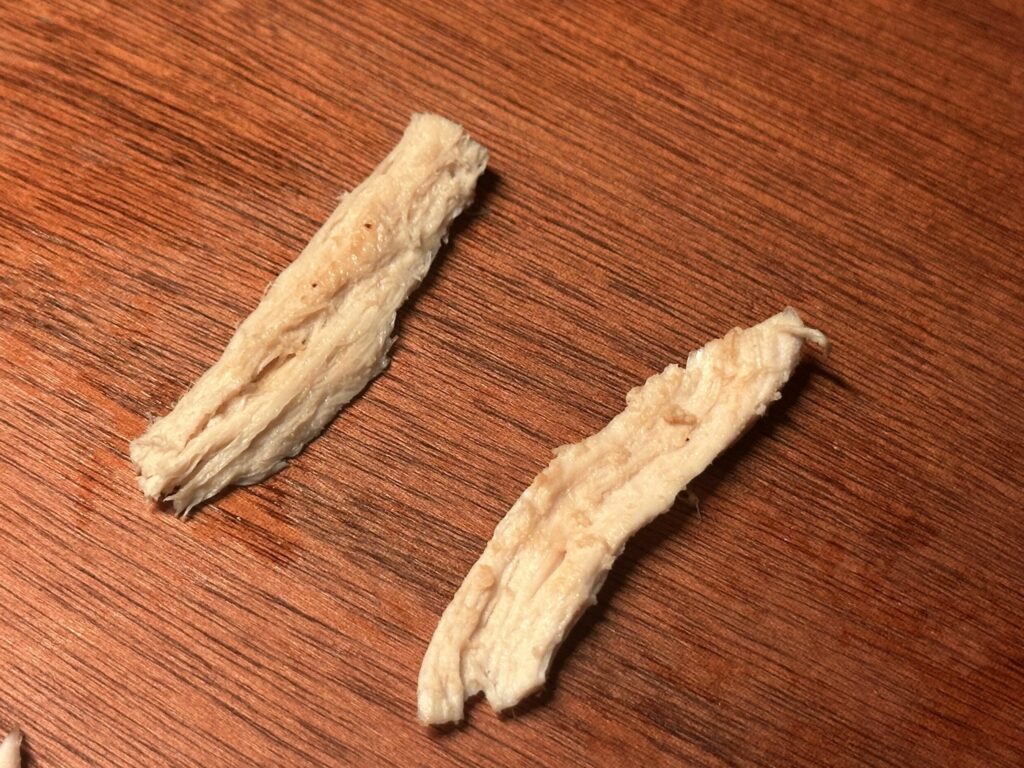

Perhaps the strongest proof of DEMOLISH’s Gen4 platform is that most meat eaters can’t tell its plant-based whole cuts from conventional meat in appearance or mouthfeel. The images above of chicken breasts and fascicles of DEMOLISH and conventional meat side-by-side, speak for themselves.

One of Gen4’s most exciting features is its ability to customize meat beyond the species level, and capture the natural variations found in conventional animal cuts. By precisely engineering both juicy and chewy sections within the same piece, they are able to recreate the authentic texture complexity that defines premium meat experiences. Gen4 cuts are also able to fuse multiple muscle structures, such as combining the major and minor pectoral muscles of a chicken breast. The Gen4 platform also has accurate sustained juiciness, which matches conventional meat from the first to the last chew.

One of Gen4’s most exciting features is its ability to customize meat beyond the species level, and capture the natural variations found in conventional animal cuts. By precisely engineering both juicy and chewy sections within the same piece, they are able to recreate the authentic texture complexity that defines premium meat experiences. Gen4 cuts are also able to fuse multiple muscle structures, such as combining the major and minor pectoral muscles of a chicken breast. The Gen4 platform also has accurate sustained juiciness, which matches conventional meat from the first to the last chew.

The Gen4 platform is fully certified for commercial manufacturing, sale, and export, and can produce whole cuts in both chilled and frozen form. Their flagship chicken breast is gluten free, non-GMO, and uses just eight clean-label ingredients, creating a nutrition profile that matches conventional meat in protein, fat, sodium, and caloric content.

Operationally, Gen4 delivers several game-changing improvements over Gen3, including a 6x increase in production throughput, a 35% reduction in operational expenditure, multi-vendor ingredient flexibility enabling supply chain resilience, and cost-optimized formulation options with minimal impact on final product quality.

The alternative protein industry has reached a make-or-break point. The market needs a transformative whole cut manufacturing platform that delivers on taste, texture, nutrition, price, and scalability. The Gen4 platform is the type of breakthrough that has the potential to revive the sector by enabling the large and unexplored category of precision plant-based whole cuts.