As consumer demand increases for plant-based products and proteins, manufacturers are turning their attention to tried-and-true technology in hope of unearthing new discoveries for financial growth and company expansion. Many manufacturers are turning to crossflow membrane filtration in search of answers.

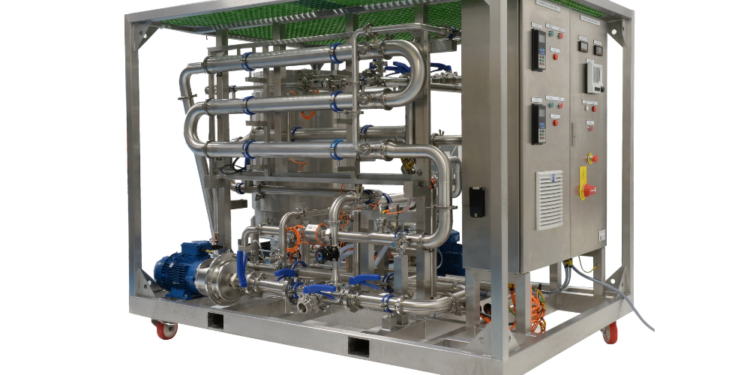

Able to provide high-quality protein yields without the risk of altering the macromolecules’ structure, crossflow membrane filtration provides a way to separate desired molecules, like protein, from the undesired molecules. Using membrane filtration avoids the loss of functional and nutritional properties, as opposed to other processes such as acid-leaching or thermal treatments. Research indicates membrane filtration can achieve a protein retention rate of up to 97%. Axium Process has been helping such companies on the road to success.

“This is not new technology,” said Jamie George, Projects & Business Development Director at Axium Process, “this is a trusted technology applied in new ways. For over 20 years we’ve helped marketleading manufacturers achieve results. The premise is the same, but the execution is a different matter entirely; we have the knowledge and experience to know where things diverge, and what to do when that happens.”

“At Axium, we tailor our solutions to customers’ specific needs, whether it’s maximising pea protein isolate for plantbased burgers or extracting soy protein for shakes.”

For companies looking to create plant-based products, membrane filtration can provide a cost-effective solution within a small footprint, helping maximise production output and efficiency. By embracing the automation of membrane filtration, companies can focus on product development and market demands, confident that their production line is up to the task.